NEXGEN Capabilities

NEXGEN offers design assistance, technical reviews, cost estimates, detailed shop drawings, BIM and 3D modeling, and 3D laser scanning, and dedicated project management. Our state of the art manufacturing facility includes CNC machinery that is vertically integrated with design for automation efficiency and accuracy.

DESIGN ASSISTANCE

Project delivery methods continue to trend towards early engagement between owners, designers, contractors, and specialty manufacturers. Our experienced staff is available for detail assistance, constructability reviews, and design-assist contracts.

PROJECT MANAGEMENT

Experienced project managers are vital to delivering products on time and on budget. We work on projects both large and small and strive to establish open lines of communications and transparency from start to finish.

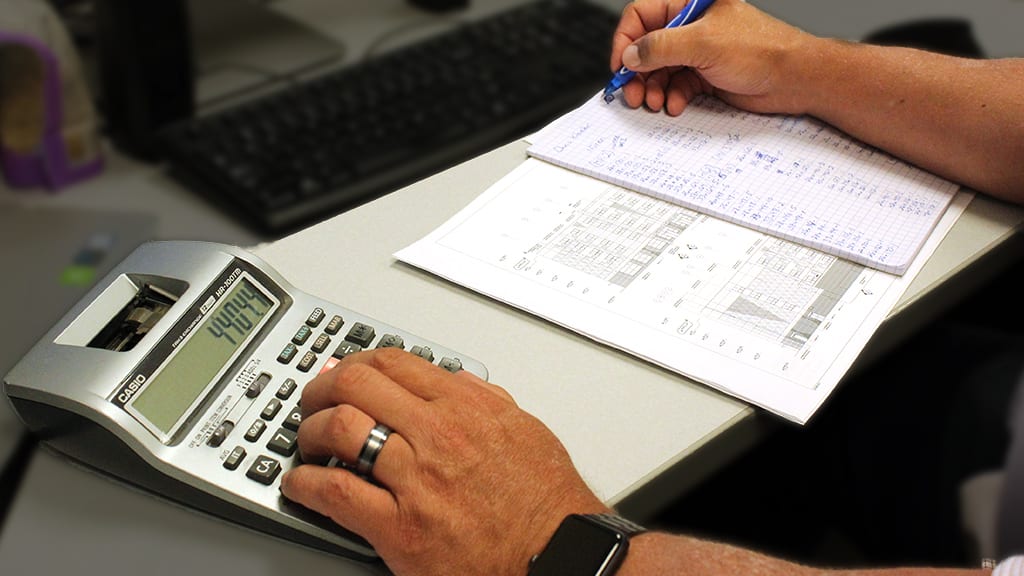

VALUE ESTIMATES

NEXGEN’s experienced estimators of timely budgets, conduct detailed take-offs, and generate comprehensive proposals free of charge.

SHOP DRAWINGS

NEXGEN’s experienced designers use the latest versions of AutoCAD®, INVENTOR®, and REVIT® to generate detailed and comprehensive shop drawings on every project.

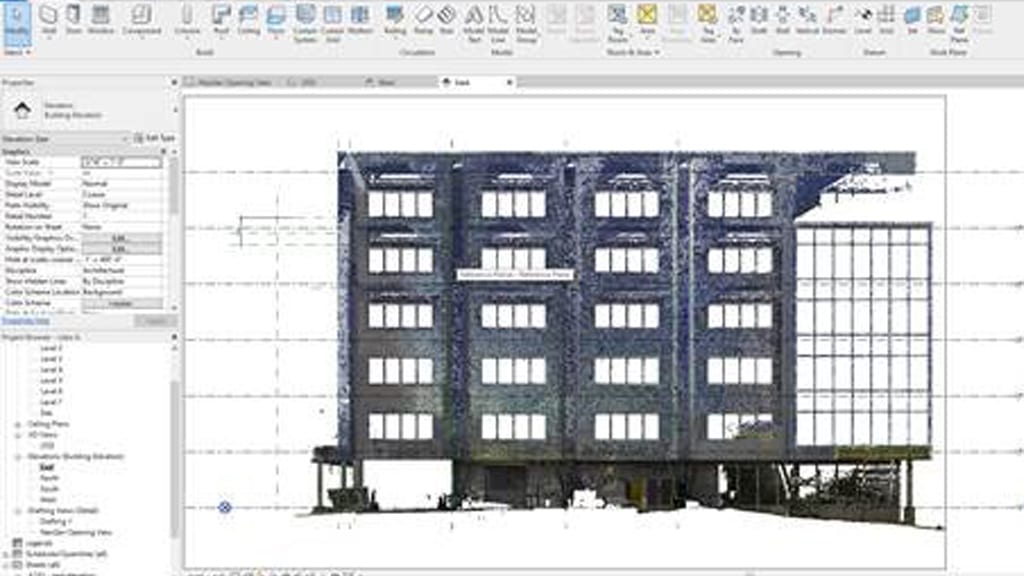

COORDINATION

NEXGEN uses the latest versions of AutoCAD®, Inventor®, our own full-scale scanning, Revit®, and more. We can generate models of our panel areas from the project’s architectural drawings as well as our scans to give us a complete picture of the building envelope.

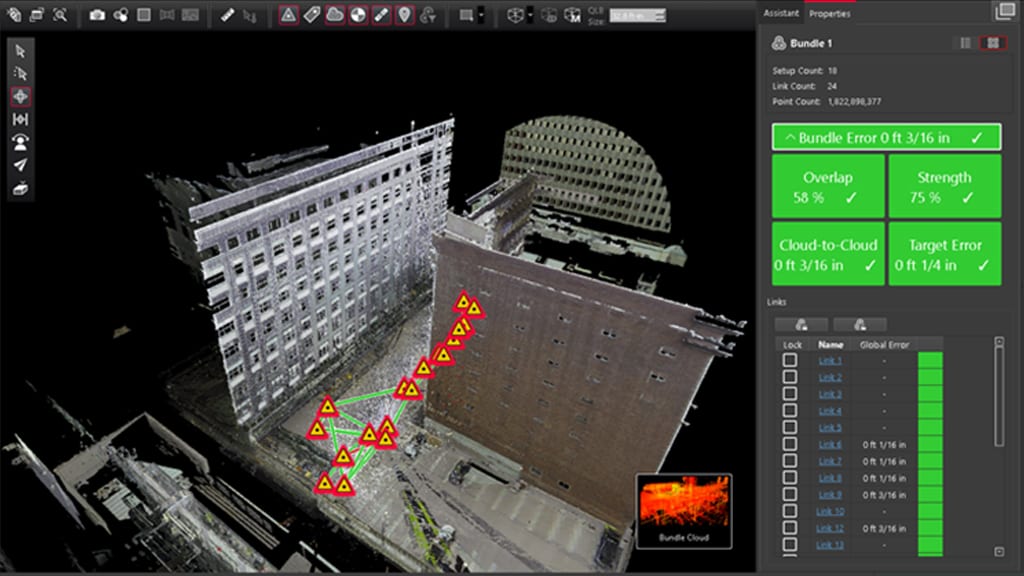

3D LASER SCANNING

We offer high speed HDR precision scanning, colored point clouds, photographic overlays, and automatic position tracking. Regardless of the size of the job, “measure twice, cut once” are our words of wisdom.

CNC ARCHITECTURAL FOLDING

- Industry 4.0 Compliant “smart machine”

- CNC automated programming

- Custom profile matching and tapering

- Bi-directional folding w/on-board high-speed slitter

- 2mm thickness capacity (20GA SS)

CNC PRECISION FOLDING SYSTEM

- Industry 4.0 Compliant “smart machine”

- CNC automated programming

- Auto-crowning corrections with vacuum part gripping

- Bi-directional folding w/ quick change tooling

- 2.5mm thickness capacity

CNC ROUTING

- CNC automated programming

- Auto-sheet loading system

- Self-contained vacuum system

- Vertical (shown) and horizontal routing platform

- MCM, aluminum plate, HPL, fiber cement, and more

CNC PLATE ROLLING

- CNC automated programming

- 4-roll design, 161” working length, 3/8” thickness capacity

- Tight radii parts (10” dia. for 4mm MCM)

- Blended radii parts, parts w/ flat and rounded area, ovals, ellipses, and tapered

- MCM, aluminum, stainless steel, steels, brass, copper, zinc

SLITTING / CUT-TO-LENGTH

- CNC automated programming

- Designed for architectural metals

- Cut-to-length and slitting

- 49.25” width capacity

- 2mm thickness capacity (16GA SS)

OTHER CAPABILITIES

- UL ES-1 Certified Edge Systems

- Large dock for material handling

- Coil handling

- Ironworker

- Shearing

Need Solutions? NEXGEN can help.

Get in touch. Let us help you with your next building enclosure project.