NEXGEN Capabilities

NEXGEN offers design assistance, technical reviews, cost estimates, detailed shop drawings, BIM and 3D modeling, and 3D laser scanning, and dedicated project management. Our state of the art manufacturing facility includes CNC machinery that is vertically integrated with design for automation efficiency and accuracy.

DESIGN ASSISTANCE

Project delivery methods continue to trend towards early engagement between owners, designers, contractors, and specialty manufacturers. Our experienced staff is available for detail assistance, constructability reviews, and design-assist contracts.

PROJECT MANAGEMENT

Experienced project managers are vital to delivering products on time and on budget. We work on projects both large and small and strive to establish open lines of communications and transparency from start to finish.

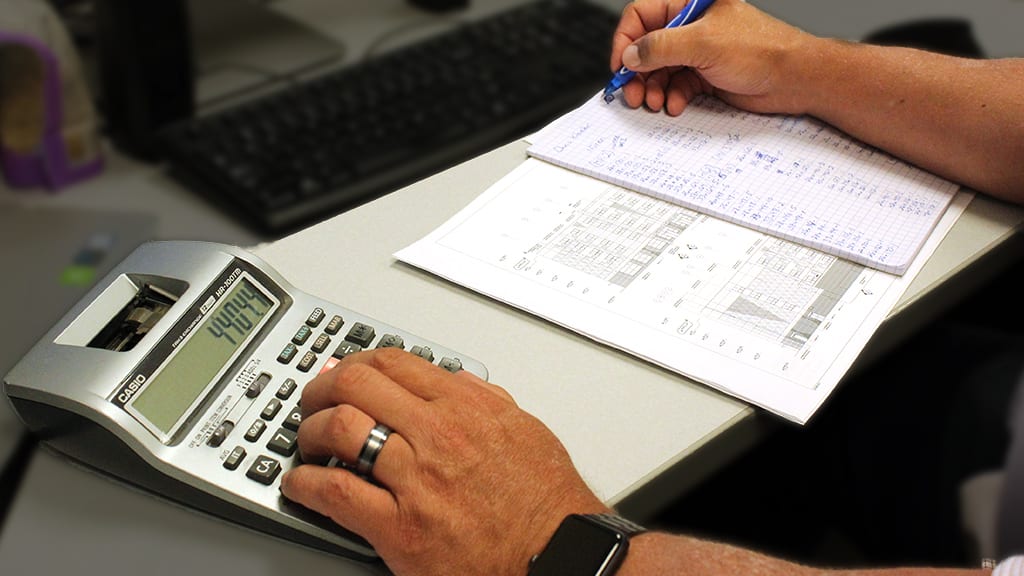

VALUE ESTIMATES

NEXGEN’s experienced estimators of timely budgets, conduct detailed take-offs, and generate comprehensive proposals free of charge.

SHOP DRAWINGS

NEXGEN’s experienced designers use cutting-edge CAD systems designed to streamline the creation of visually stunning and technically precise facades, and to generate detailed and comprehensive shop and field drawings on every project.

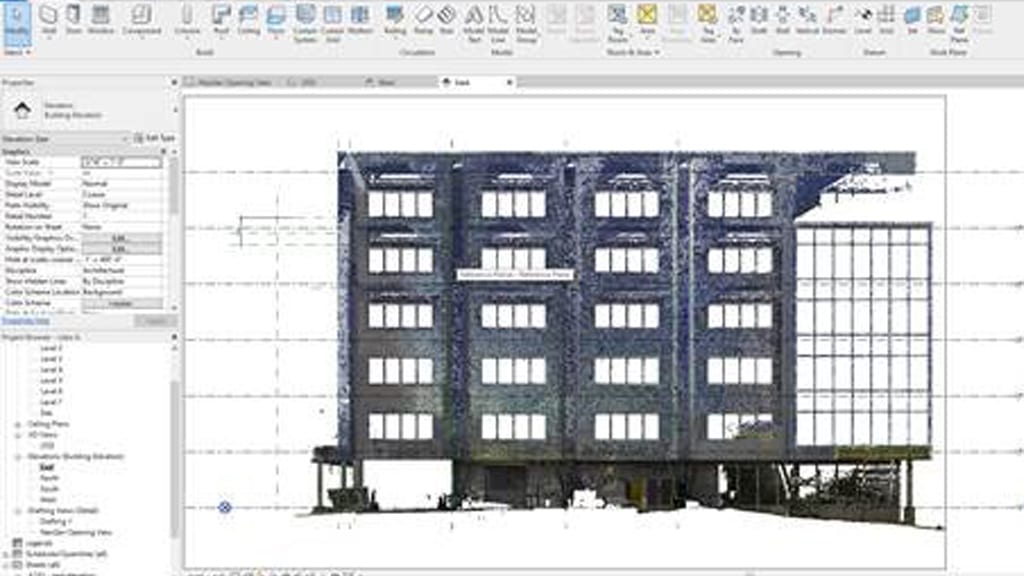

COORDINATION

NEXGEN uses advanced façade engineering applications that can produce detailed models to simply and optimize every step of the project lifecycle.

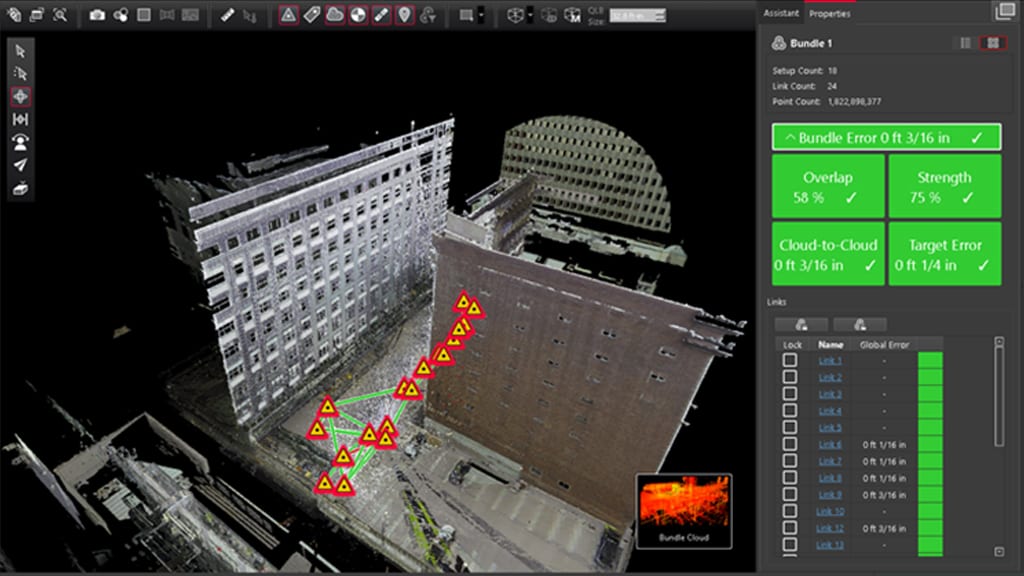

3D LASER SCANNING

We offer high speed HDR precision scanning, colored point clouds, photographic overlays, and automatic position tracking. Regardless of the size of the job, “measure twice, cut once” are our words of wisdom.

How Does NEXGEN Approach the Fabrication of Architectural Metal Building Envelope Products? What Are Their Capabilities?

Fabrication for the Modern Generation

NEXGEN uses Industry 4.0 compliant machinery in the manufacture of its architectural metal building envelope products. Smart manufacturing, or the integration of digital technologies into the manufacturing process offers enhanced productivity, efficiency, and flexibility while enabling more intelligent decision-making and customization in manufacturing and supply chain operations.

Our CNC capabilities include but are not limited to:

- Precision folding via panel benders, double folders, and press brakes

- Cutting, punching, and routing

- Rolling

- Coil processing (slit and cut to length)

- Shearing

Need Solutions? NEXGEN can help.

Get in touch. Let us help you with your next building enclosure project.